Master Techniques, From Japan to the World - 5

A heat-resistant camera that can give a clear image of the insides of high-temperature furnaces contributes to economic development and environmental protection in India

– A feasibility study and pilot project at a national steel and power plant in India

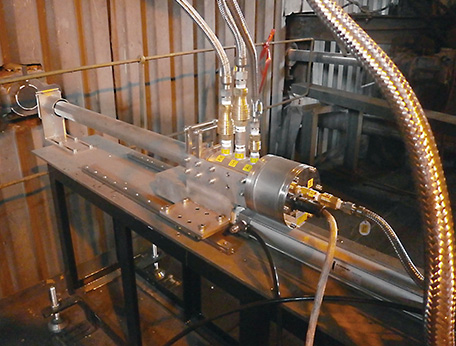

Heat-resistant camera “Furnacecope®” for monitoring high temperature furnaces. (Photo: Security Japan Co., Ltd.)

Although India has achieved rapid economic growth, it continues to face chronic power shortages and frequent power outages due to an unstable power supply. Furthermore, two of the country's key industries, electric power generation and steel, both consume energy and emit greenhouse gases (GHG) in large quantities. India is number four in the world in terms of GHG emissions, with 10% produced by the power industry and 8% by the steel industry. In order to improve this situation, the country is now fervently seeking ways to realize a stable power supply system and reduce GHG emissions by increasing the power production efficiency and energy efficiency of both industries.

The technology to meet India's needs is available to Japan in the form of heat-resistant cameras. Security Japan Co., Ltd. (Tokyo) is a company with 30 years of experience as one of the world's few manufacturers of heat-resistant and cold-resistant cameras. Furnacecope®, a heat-resistant camera developed by the company, can capture clear and detailed images of what is happening inside high-temperature industrial furnaces and boilers in power plants. Of particular note is technology that the company patented in November 1997 which enables a camera to be placed directly inside a furnace for monitoring and can withstand temperatures of over 1,200°C. Mr. Morikazu Iwami of the Security Japan sales department explained, “Up until the invention of that camera, maintenance work, such as the replacement of parts, was dependent on by-the-seat-of-the-pants planning of the people working at the furnace. Our technology made it possible for anyone to clearly observe such conditions as the degradation of furnace walls, buildup of ashes, and flames.” The product also makes it possible to more appropriately manage and repair industrial furnaces and boilers, leading to an increase in energy efficiency and energy saving, and a reduction in GHG.

Security Japan was confident that this device could be of great help to India given the issues it faces. However, having no overseas business experience of its own, the company sought out partners, eventually entering into collaboration with Ogawa Seiki Co., Ltd., a trading company that deals in chemical and medical equipment with a robust overseas network, and EX Research Institute Ltd.,1 a company skilled at market research abroad. Together, the three companies resolved to implement a project in India. In November 2013, they began the project, installing and trialing the heat-resistant camera Furnacecope at a national steel plant in Chhattisgarh State and a national coal thermal power plant in Bihar State as a project of the Verification Survey with the Private Sector for Disseminating Japanese Technologies2 supported by JICA.

A Japanese engineer explaining to local staff how to use heat-resistant cameras. (Photo: Security Japan Co., Ltd.)

Ms. Ryoko Ando of Ogawa Seiki commented, “We want people to know that there is such a thing as heat-resistant cameras, and we want them to actually use the Furnacecope. You never know how great this product is without actually using it. It would have been impossible for an SME like us to carry out full-scale market research and product demonstrations overseas on our own. We were able to partner with state-run companies for this verification survey scheme, thanks to the support from JICA. I think that was a great advantage for us.”

While the idea of a heat-resistant camera was not a new concept in itself, the Furnacecope is unique in that it can be used for a long period of time because it applies a cooling technology that effectively uses water and air. In addition, because its camera can be mounted at the tip of the cooling jacket that is placed in the furnace, the Furnacecope can capture the smallest details of the interior. Ms. Ando explained, “In India, furnace cameras often break down because they have an insufficient cooling system, so the workers at the site were initially a little doubtful. However, those same workers uttered exclamations of admiration for the Furnacecope when it clearly captured images of the furnace walls.”

The project helped to uncover new challenges. Mr. Kei Niida of the EX Research Institute explained, “Unlike in Japan, where the infrastructure is highly developed at manufacturing plants, a lot of preparation was required prior to installation in India, including countermeasures for power outages and securing quality water and air, which is necessary for cooling the camera.” Mr. Iwami at Security Japan also came to feel that in the future, his company will need to sell not only products, but entire systems including solutions to problems.

Ms. Ando of Ogawa Seiki showed enthusiasm for the future potential of the project in India, commenting, “The steel and power needs of India will continue to grow, even if that growth happens slowly. These industries consume a tremendous amount of energy. If they can raise their energy efficiency, even if only a little, it would make a great contribution to the environment and lead towards the building of a sustainable society as well. We are happy to be a part of that process with our technology.”

*1 EX Research Institute Ltd. provided external human resources for this participated in this project.

*2 Projects that consider ways to promote products and technologies developed by Japan's SMEs and other companies in developing countries through pilot and demonstration activities aimed at making the products and technologies more compatible to local conditions, based on proposals from such companies and other organizations. Projects are funded with up to a total of ¥100 million for a cooperation period of around one to three years.

<< Previous Page Next Page >>

Main Text | Statictics and Reference Materials | Stories from the field | Master Techniques, From Japan to the World - | ODA Topics